Take Your Risk Control Efforts to New Heights

CULTURE

CULTURE

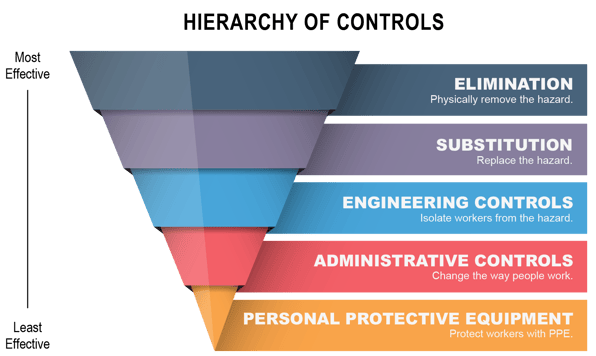

Establish a company culture that promotes safety at all levels. Part of this effort includes management’s commitment to evaluating risk control options and considering ways to help eliminate or reduce hazards that may lead to a loss.

COMMUNICATION

Encourage employees to report hazards. Management may not be aware certain hazards exist. Communication up and down the chain of command is key to raising awareness and gathering data essential to finding the proper risk control technique. Including employees in the control techniques selected also helps with their buy-in and support.

ACCOUNTABILITY

Once a risk control technique is implemented, such as wearing PPE or using a machine guard on a piece of equipment in the shop, hold employees accountable for utilizing it.

REWARDS & RECOGNITION

Praise team members for their use and support of risk control measures. Likewise, when the actions taken result in loss reduction, celebrate this achievement. Make it fun. This will encourage ongoing participation in safety initiatives.

CALL TO ACTION

-

Analyze risks to determine which hazards may be eliminated.

-

Conduct regular facility inspections to ensure risk control measures are used.

-

Consider installing fender-mounted mirrors on all tractors as an engineering control to help prevent lane change crashes.

The information in this article is provided as a courtesy of Great West Casualty Company and is part of the Value-Driven® Company program. Value-Driven Company was created to help educate and inform insureds so they can make better decisions, build a culture that values safety, and manage risk more effectively. To see what additional resources Great West Casualty Company can provide for its insureds, please contact your safety representative, or click below to find an agent.

© Great West Casualty Company 2022. The material in this publication is the property of Great West Casualty Company unless otherwise noted and may not be reproduced without its written consent by any person other than a current insured of Great West Casualty Company for business purposes. Insured should attribute use as follows: “© Great West Casualty Company 2022. Used with permission by Great West Casualty Company.”

This material is intended to be a broad overview of the subject matter and is provided for informational purposes only. Great West Casualty Company does not provide legal advice to its insureds, nor does it advise insureds on employment-related issues. Therefore, the subject matter is not intended to serve as legal or employment advice for any issue(s) that may arise in the operations of its insureds. Legal advice should always be sought from the insured’s legal counsel. Great West Casualty Company shall have neither liability nor responsibility to any person or entity with respect to any loss, action, or inaction alleged to be caused directly or indirectly as a result of the information contained herein.